Graphite Electrode Manufacturing process

Mainly made of petroleum coke and needle coke

Advantages of Graphite Electrode

1. Company Profile

Gongyi Rongxin Carbon Products Co.,Ltd. is a well-known enterprise which produces UHP carbon products and refractories.

The production equipment is excellent, the detection equipment is complete, the technical force is strong,

has high reputation in the domestic and foreign large and medium-sized enterprises.

The company has a production capacity of 150,000 tons of refined petroleum coke, 100,000 tons of pre-baked anode, 50,000 tons of carbon brick, 200,000 tons of electrode paste, special sealing paste, 50,000 tons of refractory material.

My company has domestic advanced quality inspection system and perfect after-sales service team,

to the masses of customers to provide quality products and good technical services, and is willing to cooperate sincerely with new and old friends.

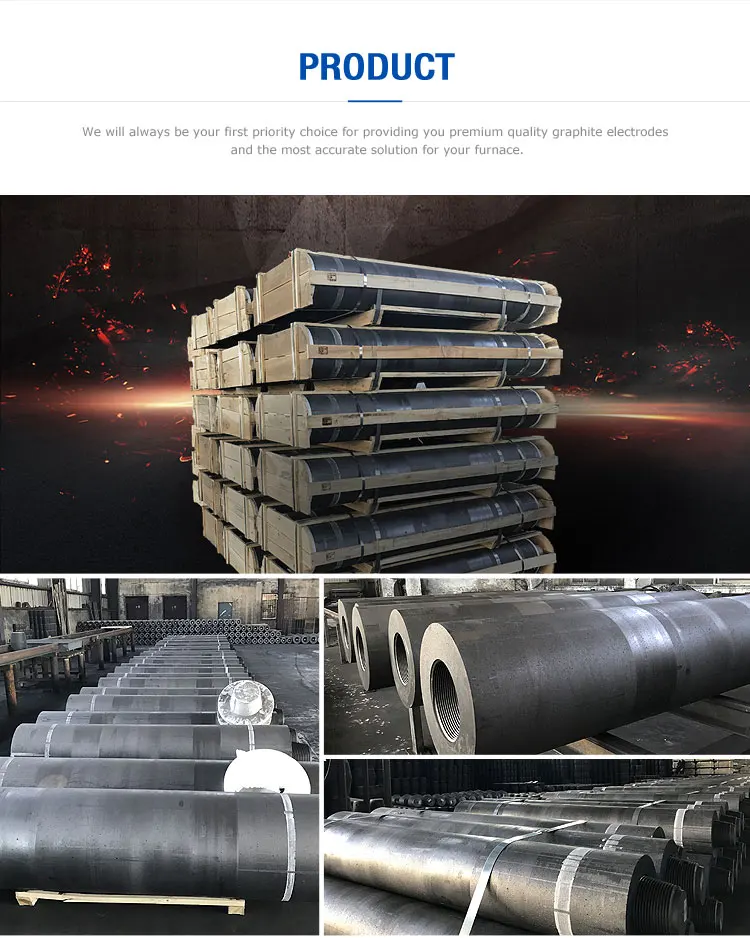

2. High Density UHP Graphite Electrode

Rongxin Carbon start its business since 1992, with the past two decades practice and cooperation with many steel plants, today we've grow into a manufactuer and trade combo, whose annual production capacity of Graphite Electrode is 60,000 MT, Carbon electrode paste of 200,000 MT. Calcined Petroleum Coke CPC of 250,000 MT.

Strong manufacturing ability and a well-connected layout agents overseas make us capable to take big orders in many countries such as Italy, Iran, Malaysia, Kazakhstan, Ukraine, Egypt, Turkey, Russia...

3. What is UHP Graphite Electrodes?

Graphite has high thermal conductivity and is very resistant to heat and impact. It also has low electrical resistance, which means it can conduct the large electrical currents needed to melt iron.

In recent years, graphite electrodes have been made even more efficient: they can now conduct even higher currents and more power.

4. CarboGraphite Graphite Electrode Specifications

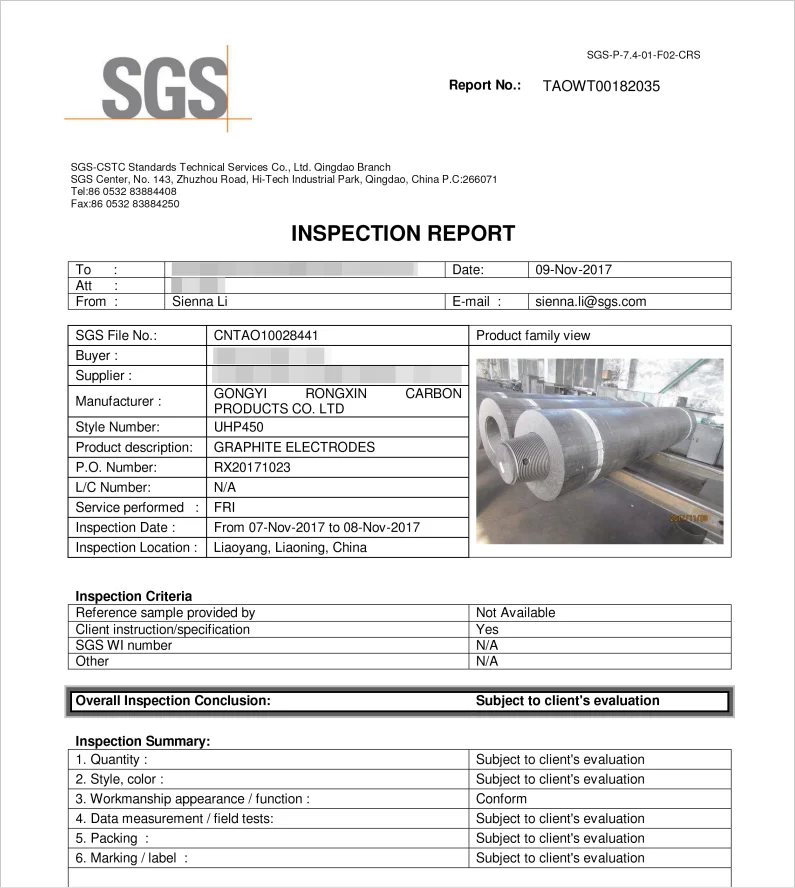

Graphite Electrodes by CarboGraphite is made to its highest quality, manufactured strictly to international standards, CarboGraphite ranks top 3 among China's UHP graphite electrode manufacturers, our UHP graphite electrodes have been exported to Europe, and Iran. SGS inspection can be made before delivery.

| Item | Unit | UHP | HP | RP | ||

| φ300-φ500 | φ550-φ800 | φ300-φ800 | φ300-φ800 | |||

| Resistivity |

Electrode Nipple |

μΩm μΩm |

4.8-5.8 3.5-4.0 |

4.6-5.8 3.5-4.0 |

5.8-6.6 3.5-4.0 |

7.0-10.0 4.0-4.5 |

| Modulus of Rupture |

Electrode Nipple |

Mpa Mpa |

10.0-14.0 20.0-24.0 |

10.0-14.0 22.0-26.0 |

10.0-13.0 20.0-23.0 |

8.0-10.0 19.0-22.0 |

| Young's Modulus |

Electrode Nipple |

Gpa Gpa |

9.0-13.0 15.0-18.0 |

10.0-14.0 16.0-19.0 |

8.0-12.0 14.0-16.0 |

7.0-9.3 12.0-14.0 |

| Bulk Density |

Electrode Nipple |

1.68-1.74 1.78-1.82 |

1.70-1.74 1.80-1.84 |

1.64-1.68 1.75-1.80 |

1.53-1.56 1.70-1.74 |

|

| CTE(100-600℃) |

Electrode Nipple |

10-6/ ℃ |

1.10-1.40 0.90-1.20

|

1.10-1.40 0.90-1.20 |

1.60-1.90 1.10-1.40 |

2.20-2.60 2.00-2.50 |

| Ash | % | 0.3 | 0.3 | 0.3 | 0.5 | |

5. Our UHP Graphite Electrode Advantages

- High Graphite Electrode Density, High Temperature Strength

- Low Thermal Expansion

- Excellent Thermal and Electrical Conductivity

- Good Machinability

6. Our UHP 500mm Graphite Electrode Application

Graphite electrodes are used for the recycling of steel in the electric arc furnace industry, so called "mini-mills".

In the steelmaking process, iron scrap gets melted in an electric arc furnace and recycled. Graphite electrodes, a kind of conductor, are an essential component in this kind of furnace.They can melt scrap at a temperature of about 1600℃.

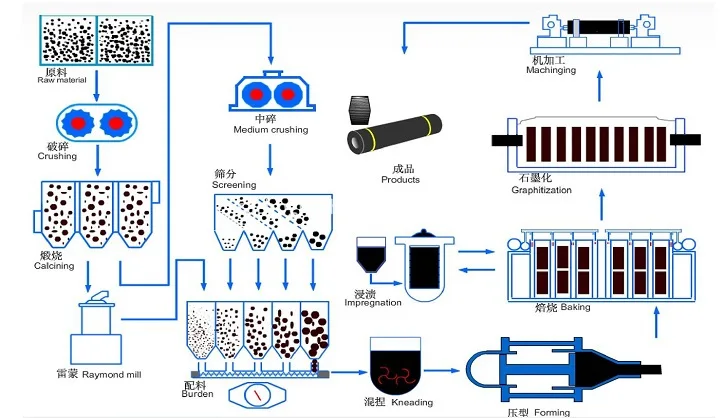

7. UHP Graphite Electrode Manufacturing Process

Needle coke has the features of needle-like crystals develop and low thermal expansion coefficient.

Pitch is produced by heat treatment of coal tar carbonizes under heat (50% yield).

Needle coke and pitch are mixed and then molded. Heat treatment is then applied in the baking and graphitization process to form the finished product.

8. Quality Assurance of Our UHP Graphite Electrode

RP HP UHP Graphite electrode by Rongxin Carbon is made to last, thus make Rongxin carbon as a reputed and trusted name on market. We've provided the best value for quality, price, and service to our customers for more than 20 years. Our business success rooted in "No compromise on quality", third party inspection such as SGS is available before delivery.

9. Pricing

As the graphite electrode demand is unstable, so as the graphite electrode global prices, Ask us now for our latest version of graphite electrode price graph.

Reach us now for Graphite Electrode pricing. We are pleased to discuss your purchase requirements.

daisy@smeltingmateri

Graphite Electrode Manufacturing process

Advantages of Graphite Electrode

daisy@smeltingmateri

UHP350mm Graphite Electrode

Graphite Electrode Specification

UHP Graphite Electrode Advantages

UHP Graphite Electrode Manufacturing Process

cindy@smeltingmateri

UHP400 Graphite electrodes are used for the recycling of steel in the electric arc furnace industry, so called “mini-mills”. They are also used in the refining of steel as well as in the non ferrous industries.